Both our core competency and our passion

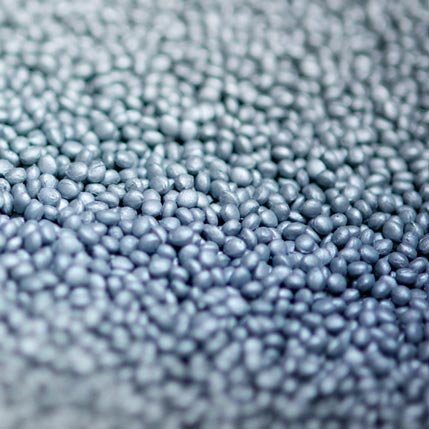

Extrusion, the core component of the manufacturing of films, has intentionally been positioned very broadly within the company. Our objective is to provide our customers with a single-source product portfolio that is a broad a possible, in the quality that they are accustomed to.

- 13 Extruder (LDPE-based)

- Mono qualities (single layer construction)

- Coex-3S (3-layer construction)

- Coex-5S (5-layer construction)

- Heatshrinking tubular film (for automatic packaging systems)

- Stretch hood film (stretch tubular film)

- Separating layer qualities (Coex-PP or Coex-Surlyn)

- Films for automatic machines

- Special films

- Tubular film circumferences of 800 mm to 6800 mm

- Maximum layer width: 2500 mm

- Thicknesses of 0.030 mm to 0.250 mm

- Macro perforation (3 mm, 6 mm, 8 mm, 10 mm diameter)

- Micro perforation (needle perforation, cold or hot needle)

- Printing pre-treatment (full or partial area)